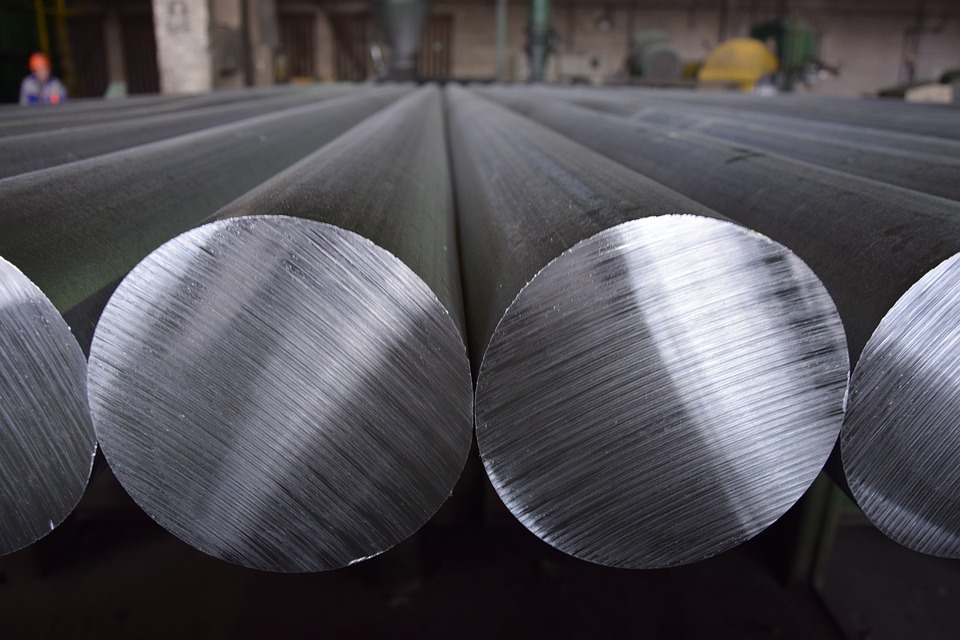

Aluminum has long been a favorite material of manufacturers to work with because of its abundance, low price, and ease of handling when it’s molded into different shapes. However, a huge concern about the metal is that it is incredibly soft and easily gives in to pressure. Thanks to the work of researchers, however, aluminum might soon be as tough as stainless steel.

The new development was courtesy of researchers from the School of Materials Engineering at Purdue University. According to the paper they published, making the lightweight metal as strong as stainless steel was all about altering the microstructure of the material. This is easier said than done, of course, but the researchers accomplished it with professor Xinghang Zhang at the head of the team.

"Most lightweight aluminum alloys are soft and have inherently low mechanical strength, which hinders more widespread industrial application," Zhang said. "However, high-strength, lightweight aluminum alloys with strength comparable to stainless steels would revolutionize the automobile and aerospace industries."

Without getting too technical regarding the details, the researchers basically introduced what’s called “stacking faults” into the material. These are distortions in the crystal, which have proven notoriously difficult to do with aluminum. The metal simply had too high of a “stacking fault energy.”

As counterproductive as introducing flaws into the material might sound, this actually makes the metal stronger and more ductile. A stacking fault type called the 9R phase is of particular interest to the researchers because of its potential, Phys.org reports.

"It has been shown that twin boundaries are difficult to be introduced into aluminum. The formation of the 9R phase in aluminum is even more difficult because of its high stacking fault energy," Zhang explained with regards to the material. "You want to introduce both nanotwins and 9R phase in nanograined aluminum to increase strength and ductility and improve thermal stability."

NASA Resumes Cygnus XL Cargo Docking with Space Station After Software Fix

NASA Resumes Cygnus XL Cargo Docking with Space Station After Software Fix  SpaceX Starship Test Flight Reaches New Heights but Ends in Setback

SpaceX Starship Test Flight Reaches New Heights but Ends in Setback  FDA Lifts REMS Requirement for CAR-T Cell Cancer Therapies

FDA Lifts REMS Requirement for CAR-T Cell Cancer Therapies  Is space worth the cost? Accounting experts say its value can’t be found in spreadsheets

Is space worth the cost? Accounting experts say its value can’t be found in spreadsheets  Neuralink Plans High-Volume Brain Implant Production and Fully Automated Surgery by 2026

Neuralink Plans High-Volume Brain Implant Production and Fully Automated Surgery by 2026  Trump and Merck KGaA Partner to Slash IVF Drug Costs and Expand Fertility Coverage

Trump and Merck KGaA Partner to Slash IVF Drug Costs and Expand Fertility Coverage  SpaceX Prioritizes Moon Mission Before Mars as Starship Development Accelerates

SpaceX Prioritizes Moon Mission Before Mars as Starship Development Accelerates  Tabletop particle accelerator could transform medicine and materials science

Tabletop particle accelerator could transform medicine and materials science  SpaceX’s Starship Completes 11th Test Flight, Paving Way for Moon and Mars Missions

SpaceX’s Starship Completes 11th Test Flight, Paving Way for Moon and Mars Missions  Eli Lilly’s Inluriyo Gains FDA Approval for Advanced Breast Cancer Treatment

Eli Lilly’s Inluriyo Gains FDA Approval for Advanced Breast Cancer Treatment  Trump Administration to Launch Autism Initiatives Targeting Acetaminophen Use and New Treatment Options

Trump Administration to Launch Autism Initiatives Targeting Acetaminophen Use and New Treatment Options  CDC Vaccine Review Sparks Controversy Over Thimerosal Study Citation

CDC Vaccine Review Sparks Controversy Over Thimerosal Study Citation