GE Aerospace is accelerating automation and AI-driven innovation at its Singapore engine repair hub as global airlines grapple with maintenance delays, parts shortages, and extended turnaround times. At the center of this transformation is technician Suresh Sinnaiyan, who has spent more than a decade manually repairing jet-engine compressor blades. Today, he is helping program robots to replicate the precision sanding and blending techniques traditionally performed by skilled human hands.

The initiative supports GE Aerospace’s broader strategy to ease aviation supply chain bottlenecks caused by unexpected wear in next-generation jet engines. These durability issues have grounded aircraft, forced airlines to extend the life of older jets, and stretched maintenance repair and overhaul (MRO) timelines to several months. Airlines have voiced concerns over rising engine servicing costs, while manufacturers argue they are investing heavily to expand capacity after significant research and development spending.

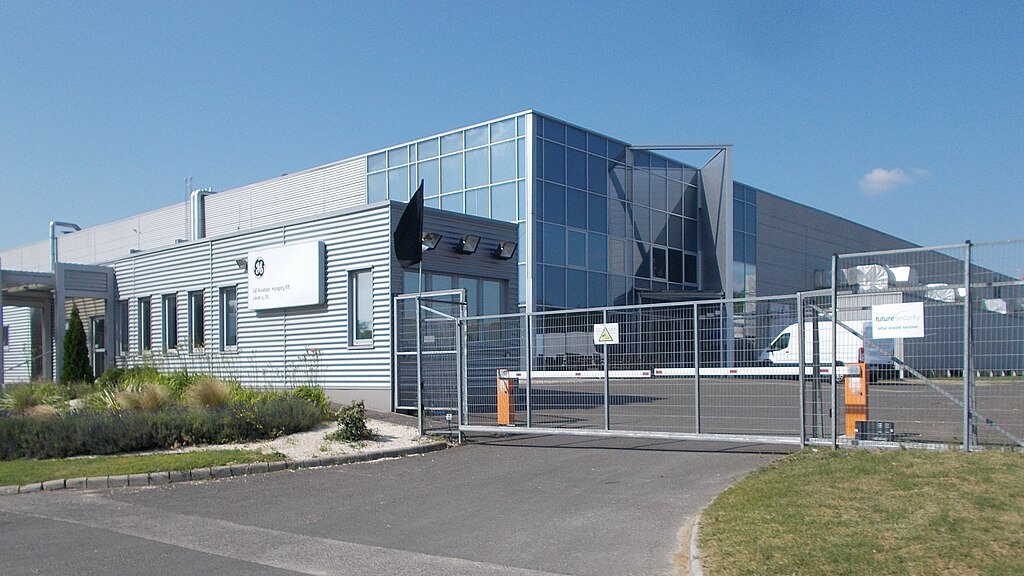

Singapore plays a critical role in GE’s solution. The company is upgrading its 2,000-employee facility with advanced robotics, digital tools, and artificial intelligence as part of an investment plan that could reach $300 million. GE aims to increase repair output by 33% without expanding the site’s physical footprint, focusing instead on workflow optimization, lean manufacturing practices, and automation.

Repairing used engine components rather than replacing them with newly manufactured parts reduces costs and turnaround time for airlines. GE says certain repair processes can cut both servicing time and expenses by up to 50%. For example, turnaround times for CFM56 turbine nozzle repairs have improved from 40 days in 2021, with a target of 21 days by 2028. The facility is also preparing to service newer LEAP engines entering overhaul cycles.

By capturing specialized manual skills in repeatable robotic systems, GE Aerospace aims to boost productivity, reduce dependence on scarce labor, and strengthen global aviation maintenance resilience as industry demand stabilizes.

Indonesia Issues Stern Warning to Meta Over Online Gambling and Disinformation

Indonesia Issues Stern Warning to Meta Over Online Gambling and Disinformation  Defense Contractors Move to Drop Anthropic AI After Trump Administration Ban

Defense Contractors Move to Drop Anthropic AI After Trump Administration Ban  Nintendo Share Sale: MUFG and Bank of Kyoto to Sell Stakes in Strategic Unwinding

Nintendo Share Sale: MUFG and Bank of Kyoto to Sell Stakes in Strategic Unwinding  JD.com Misses Q4 Revenue Estimates as China’s Weak Consumer Demand and E-Commerce Competition Intensify

JD.com Misses Q4 Revenue Estimates as China’s Weak Consumer Demand and E-Commerce Competition Intensify  Big Tech Signs White House Pledge to Fund Power for AI Data Centers

Big Tech Signs White House Pledge to Fund Power for AI Data Centers  Lockheed Martin Secures $1.9B U.S. Air Force Contract for C-130J Training and Maintenance Systems

Lockheed Martin Secures $1.9B U.S. Air Force Contract for C-130J Training and Maintenance Systems  FDA Warns Novo Nordisk Over Misleading Ozempic Ad Claims

FDA Warns Novo Nordisk Over Misleading Ozempic Ad Claims  OpenAI and U.S. Defense Department Update Agreement to Clarify AI Usage Terms

OpenAI and U.S. Defense Department Update Agreement to Clarify AI Usage Terms  AWS Data Centers in UAE and Bahrain Hit by Drone Strikes Amid Middle East Conflict

AWS Data Centers in UAE and Bahrain Hit by Drone Strikes Amid Middle East Conflict  OpenAI Secures $110 Billion Funding Round at $840 Billion Valuation Ahead of IPO

OpenAI Secures $110 Billion Funding Round at $840 Billion Valuation Ahead of IPO  U.S. Officials Review Tencent’s Stakes in Epic Games, Riot Games Over Security Concerns

U.S. Officials Review Tencent’s Stakes in Epic Games, Riot Games Over Security Concerns  Moderna to Pay Up to $2.25B to Settle LNP Patent Dispute Over COVID-19 Vaccine Technology

Moderna to Pay Up to $2.25B to Settle LNP Patent Dispute Over COVID-19 Vaccine Technology  Rio Tinto Advances Gallium Extraction Project in Canada with Federal Funding Support

Rio Tinto Advances Gallium Extraction Project in Canada with Federal Funding Support  Nvidia to Launch New AI Inference Processor to Boost OpenAI Performance

Nvidia to Launch New AI Inference Processor to Boost OpenAI Performance  Facebook Outage Disrupts Thousands of Users Across the United States

Facebook Outage Disrupts Thousands of Users Across the United States  Nvidia CEO Jensen Huang Says $100B OpenAI Investment Unlikely as AI Demand Surges

Nvidia CEO Jensen Huang Says $100B OpenAI Investment Unlikely as AI Demand Surges