The market environment across the globe has become more competitive in recent years. The manufacturing sector is now booming, from SMEs to large-scale businesses. Amidst the fast-paced market trend, efficiency is vital in winning the manufacturing wars. It is no surprise that companies invest in data-driven and automated manufacturing systems.

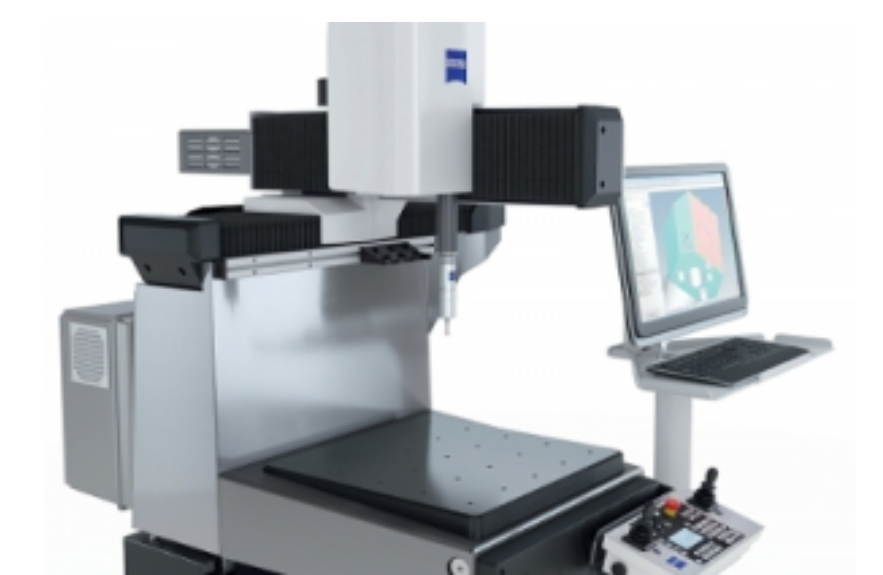

Manufacturers must ensure the consistency and accuracy of the product’s dimensions. They must take care of the 3D geometric appearance because measurement errors may disrupt the process. Fortunately, a coordinate measuring machine (CMM) helps businesses meet customers’ demands and expectations. This article will discuss the function of a CMM in enhancing efficiency.

Quality Reliability

CMMs provide manufacturers with a quick and correct path to measure every part of the object. Through CMM services like dimensional analysis, workers can check all product design aspects. The machine ensures the accuracy and precision of all dimensions, regardless of complexity. The good thing about CMM is that workers no longer have to transfer components to a laboratory. The measurement can be done with ease and correctness. It has become more crucial now that businesses are geared toward quality and quantity improvement.

It can also determine if there are dimension deviations, especially in high-quality parts. Aside from the measurement, it checks the positioning and relationship of every piece. The machine is crucial in revolving parts because even the slightest errors may affect their movement and vibration. Measuring complex surfaces like airplane wings and turbine blades is also possible. Doing these in huge batches can be challenging, and often, manual checking is needed. But they still can be automated while ensuring their precision and checking them one by one.

Flexible and Economical

Before, CMMs were only usable in air-controlled labs. Today, a wide variety of CMMs are available in the market. There are many shop-floor ready and portable CMMs for production and cell manufacturing. So workers do not have to remove each part and take it to the lab for measurement. CMMs have become more flexible, which helps manufacturers to meet their goals and save money and time. They have new software and laser scanners that allow workers to measure every part quickly.

Warning Signals

Error checking in CMM is not limited to dimensions alone. CMMs can also send warning signals for product defects, wear out, and thermal drift. For many revolving parts, workers have to check if oscillations affect the smoothness of every movement. They spend more time correcting errors in geometrical parameters and reducing friction. But CMMs may spot inaccuracies in a snap.

Longevity

CMMs remain durable and effective for two decades. They may exceed thirty years if properly maintained. Even the used CMM equipment may still function like a new one.

Bottom Line

Your manufacturing goals tell how you want to maximize efficiency with a CMM. Its precision and versatility allow you to use it for automated manufacturing and redesigning. Technology continues to move forward, and CMMs are keeping up with it. They always guarantee productivity to meet the demands and expectations of the market.

This article does not necessarily reflect the opinions of the editors or management of EconoTimes

Sony Q3 Profit Jumps on Gaming and Image Sensors, Full-Year Outlook Raised

Sony Q3 Profit Jumps on Gaming and Image Sensors, Full-Year Outlook Raised  OpenAI Expands Enterprise AI Strategy With Major Hiring Push Ahead of New Business Offering

OpenAI Expands Enterprise AI Strategy With Major Hiring Push Ahead of New Business Offering  CK Hutchison Launches Arbitration After Panama Court Revokes Canal Port Licences

CK Hutchison Launches Arbitration After Panama Court Revokes Canal Port Licences  Instagram Outage Disrupts Thousands of U.S. Users

Instagram Outage Disrupts Thousands of U.S. Users  Tencent Shares Slide After WeChat Restricts YuanBao AI Promotional Links

Tencent Shares Slide After WeChat Restricts YuanBao AI Promotional Links  Anthropic Eyes $350 Billion Valuation as AI Funding and Share Sale Accelerate

Anthropic Eyes $350 Billion Valuation as AI Funding and Share Sale Accelerate  Missouri Judge Dismisses Lawsuit Challenging Starbucks’ Diversity and Inclusion Policies

Missouri Judge Dismisses Lawsuit Challenging Starbucks’ Diversity and Inclusion Policies  Baidu Approves $5 Billion Share Buyback and Plans First-Ever Dividend in 2026

Baidu Approves $5 Billion Share Buyback and Plans First-Ever Dividend in 2026  Australian Scandium Project Backed by Richard Friedland Poised to Support U.S. Critical Minerals Stockpile

Australian Scandium Project Backed by Richard Friedland Poised to Support U.S. Critical Minerals Stockpile  Prudential Financial Reports Higher Q4 Profit on Strong Underwriting and Investment Gains

Prudential Financial Reports Higher Q4 Profit on Strong Underwriting and Investment Gains  Toyota’s Surprise CEO Change Signals Strategic Shift Amid Global Auto Turmoil

Toyota’s Surprise CEO Change Signals Strategic Shift Amid Global Auto Turmoil  Ford and Geely Explore Strategic Manufacturing Partnership in Europe

Ford and Geely Explore Strategic Manufacturing Partnership in Europe  TSMC Eyes 3nm Chip Production in Japan with $17 Billion Kumamoto Investment

TSMC Eyes 3nm Chip Production in Japan with $17 Billion Kumamoto Investment  AMD Shares Slide Despite Earnings Beat as Cautious Revenue Outlook Weighs on Stock

AMD Shares Slide Despite Earnings Beat as Cautious Revenue Outlook Weighs on Stock  SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off

SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off  Once Upon a Farm Raises Nearly $198 Million in IPO, Valued at Over $724 Million

Once Upon a Farm Raises Nearly $198 Million in IPO, Valued at Over $724 Million  Nasdaq Proposes Fast-Track Rule to Accelerate Index Inclusion for Major New Listings

Nasdaq Proposes Fast-Track Rule to Accelerate Index Inclusion for Major New Listings