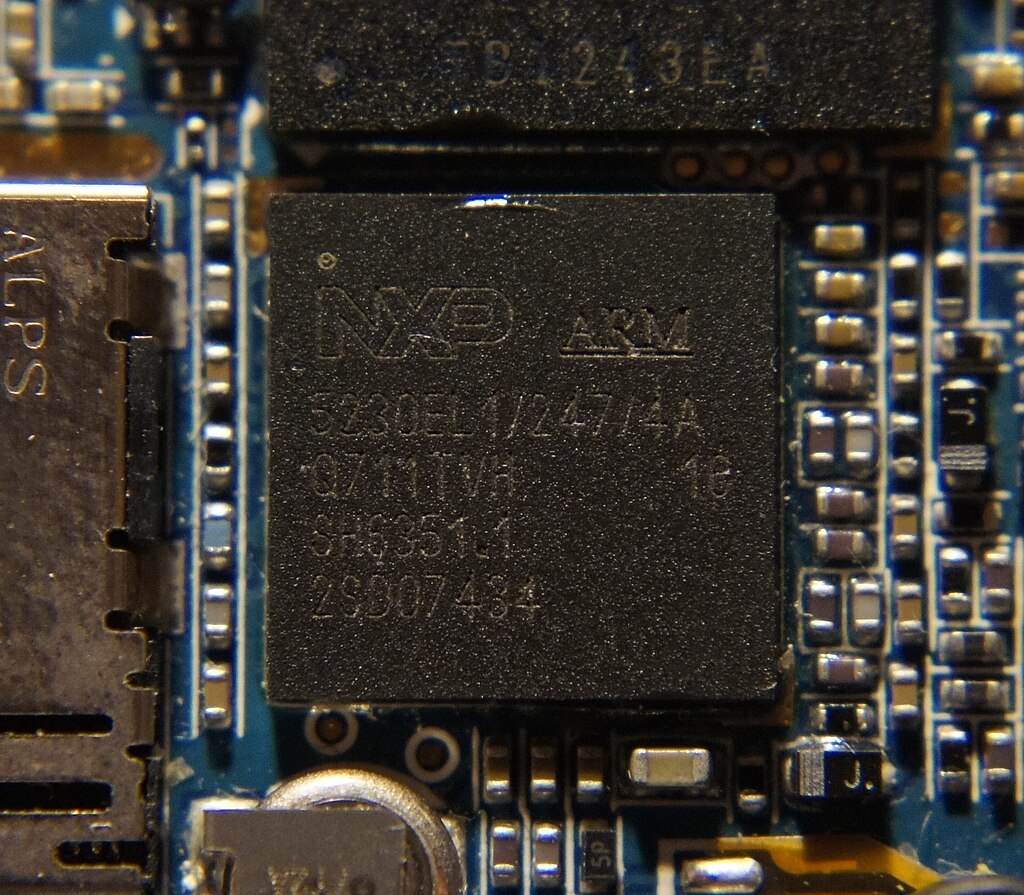

A factory in China’s industrial south has unexpectedly become a global choke point for automotive chips, exposing deep vulnerabilities in the auto sector’s supply chain. Despite previous promises to strengthen semiconductor sourcing after the pandemic-era shortages, automakers were caught off guard again—this time by geopolitically driven disruption involving Dutch chipmaker Nexperia and its Chinese parent, Wingtech.

The crisis began when the Dutch government temporarily took control of Nexperia’s Netherlands headquarters over fears that sensitive technology could be accessed by China. Beijing retaliated by blocking exports of Nexperia’s low-cost but essential automotive chips produced in Dongguan. Though inexpensive and considered basic components, these semiconductors are vital for functions such as braking systems and power windows. The sudden halt forced manufacturers like Nissan and Honda to cut production and pushed Bosch to scale back working hours.

Industry experts say the situation highlights a major shortcoming in global supply-chain strategy: automakers prepared for natural disasters and market shocks but did not anticipate geopolitical pressure targeting low-end semiconductor components. Executives and analysts note that years of just-in-time inventory practices and limited supplier diversification created the perfect setup for disruption. Some major suppliers, including Bosch, did not have enough alternative chip sources ready despite purchasing massive volumes from Nexperia annually.

The situation was further strained when Nexperia began requiring payments in yuan, slowing transactions and leaving chips piled up at the factory before conditions eased. China eventually allowed limited exports to resume after high-level political talks, narrowly preventing production shutdowns at major suppliers like ZF Group and Hella.

While companies such as Toyota remained relatively insulated due to long-standing stockpiling policies, most automakers now face renewed pressure to build more resilient, regionally diversified chip inventories. However, replacing or re-qualifying components can take months to a year, since many chips are integrated directly into vehicle modules and cannot be easily swapped.

As consultants warn, the industry will again talk about resilience and diversification—but implementing these strategies will be expensive. The Nexperia episode underscores how even low-tech components can become powerful geopolitical levers and disrupt global manufacturing at scale.

New York Legalizes Medical Aid in Dying for Terminally Ill Patients

New York Legalizes Medical Aid in Dying for Terminally Ill Patients  U.S. Announces Additional $6 Million in Humanitarian Aid to Cuba Amid Oil Sanctions and Fuel Shortages

U.S. Announces Additional $6 Million in Humanitarian Aid to Cuba Amid Oil Sanctions and Fuel Shortages  Panama Supreme Court Voids Hong Kong Firm’s Panama Canal Port Contracts Over Constitutional Violations

Panama Supreme Court Voids Hong Kong Firm’s Panama Canal Port Contracts Over Constitutional Violations  Nvidia Nears $20 Billion OpenAI Investment as AI Funding Race Intensifies

Nvidia Nears $20 Billion OpenAI Investment as AI Funding Race Intensifies  American Airlines CEO to Meet Pilots Union Amid Storm Response and Financial Concerns

American Airlines CEO to Meet Pilots Union Amid Storm Response and Financial Concerns  Pentagon and Anthropic Clash Over AI Safeguards in National Security Use

Pentagon and Anthropic Clash Over AI Safeguards in National Security Use  SpaceX Pushes for Early Stock Index Inclusion Ahead of Potential Record-Breaking IPO

SpaceX Pushes for Early Stock Index Inclusion Ahead of Potential Record-Breaking IPO  TrumpRx Website Launches to Offer Discounted Prescription Drugs for Cash-Paying Americans

TrumpRx Website Launches to Offer Discounted Prescription Drugs for Cash-Paying Americans  Once Upon a Farm Raises Nearly $198 Million in IPO, Valued at Over $724 Million

Once Upon a Farm Raises Nearly $198 Million in IPO, Valued at Over $724 Million  U.S. to Begin Paying UN Dues as Financial Crisis Spurs Push for Reforms

U.S. to Begin Paying UN Dues as Financial Crisis Spurs Push for Reforms  SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off

SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off  Elon Musk’s Empire: SpaceX, Tesla, and xAI Merger Talks Spark Investor Debate

Elon Musk’s Empire: SpaceX, Tesla, and xAI Merger Talks Spark Investor Debate  Trump Lifts 25% Tariff on Indian Goods in Strategic U.S.–India Trade and Energy Deal

Trump Lifts 25% Tariff on Indian Goods in Strategic U.S.–India Trade and Energy Deal  Trump Family Files $10 Billion Lawsuit Over IRS Tax Disclosure

Trump Family Files $10 Billion Lawsuit Over IRS Tax Disclosure  Trump Says “Very Good Talks” Underway on Russia-Ukraine War as Peace Efforts Continue

Trump Says “Very Good Talks” Underway on Russia-Ukraine War as Peace Efforts Continue  Google Cloud and Liberty Global Forge Strategic AI Partnership to Transform European Telecom Services

Google Cloud and Liberty Global Forge Strategic AI Partnership to Transform European Telecom Services