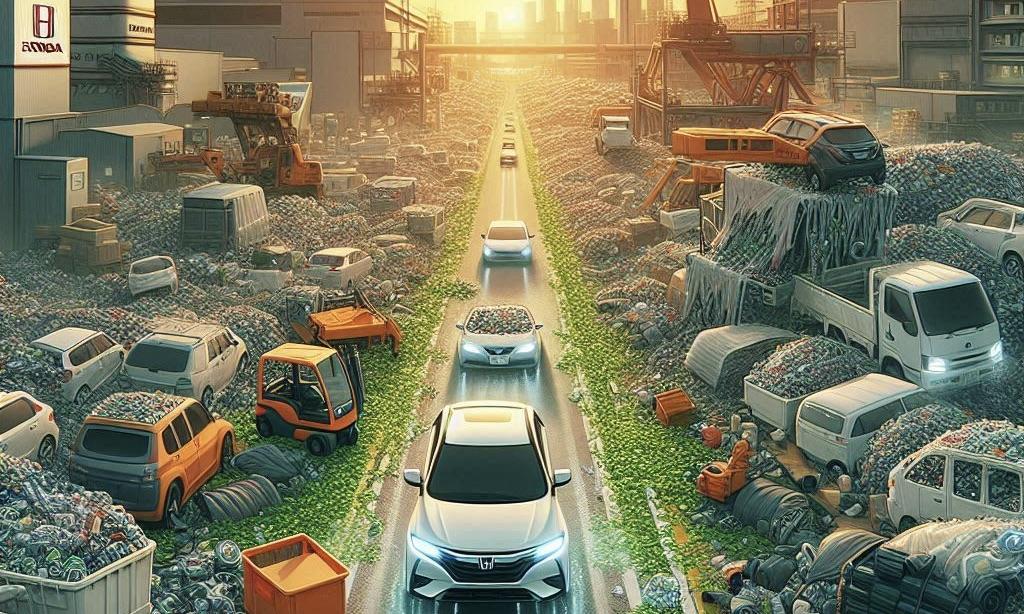

Honda and Nissan are spearheading a movement in Japan to incorporate recycled plastic into vehicle manufacturing. In response to upcoming European regulations, these automakers are developing supply chains and technologies to meet new environmental standards, aiming for a sustainable future in automotive production.

Honda and Nissan Pioneer Recycled Plastic Supply Chains to Meet Upcoming EU Vehicle Regulations

Nikkei has learned that Honda Motor and Nissan Motor are among the Japanese automakers establishing supply channels for recycled plastic to comply with the anticipated new European regulations and make their vehicles more environmentally friendly.

Plastic is a critical component of automobile production, serving as fenders, interiors, and other elements. According to a 2023 proposal by the European Commission, a minimum of 25% of the plastic in a new vehicle would be recycled. The potential for noncompliant new cars to be prohibited from being sold in the European Union is heightened because this regulation would be fully implemented as early as 2031.

The Tokyo-based Plastic Waste Management Institute reported that auto parts accounted for only approximately 3% of Japan's total plastic recycled into new products in 2022. The time-consuming process of sorting plastic fragments after vehicles are scrapped has made it difficult for automakers in Japan to recycle plastics.

According to Nikkei Asia, Honda aims to establish a supply chain for recycled plastic by approximately 2040 through partnerships with recycling companies and chemical manufacturers. The number of plastic types used in new vehicles is proposed to be reduced by approximately 60% to six or seven, simplifying the recycling station sorting process. The Honda E, Honda's inaugural mass-produced electric vehicle, employed approximately 25 plastic varieties.

Honda will seek the assistance of Mitsubishi Chemical Group and Toray Industries to convert the plastic collected into materials suitable for automobile use. Impurities may compromise the strength of the plastic. The collaborators aspire to create and market technologies that enhance the quality of recycled plastic to a level comparable to that of current products.

Other members of the automotive industry are also pursuing recycled plastic. Nissan and Renault will implement an initiative to recycle plastic from discarded electric vehicles and incorporate it into new cars manufactured in Europe. Nissan is contemplating the possibility of investing in a Renault recycling unit; however, the investment's specifics will be determined later.

Toyota and Subaru Set Ambitious Targets for Recycled Plastic in Vehicles Amid Rising Costs

By 2030, Toyota Motor has established a goal of ensuring that recycled plastic comprises 30% or more of the plastic used in new vehicles manufactured in Japan and Europe, according to their weight.

Toyota's Land Cruiser 250 series of sport utility vehicles is upholstered with fabric derived from plastic bottles collected in-house by the automaker. Toyota nearly doubled the amount of recycled plastic used in the C-HR small SUV sold in Europe compared to its predecessor.

Subaru's objective is to ensure that by 2030, recycled materials comprise at least 25% of the plastic used in new in-house models sold globally.

Their increased cost impedes the widespread adoption of recycled plastic auto parts. The cost of recycled plastic is estimated to be between 50% and three times that of conventional plastic. A substantial rise in the utilization of recycled plastic may adversely affect automakers' earnings.

The Japanese government will assist the endeavor by establishing a public-private partnership as early as September. The Japan Automobile Manufacturers Association (JAMA), of which Toyota and Honda are members, and the Plastic Waste Management Institute are among the approximately ten organizations anticipated to be included in this group, with the Environment Ministry serving as the coordinator.

The members of this new entity will collaborate on matters such as providing recycled plastic. The ministry will evaluate the necessity of investing.

Mercedes-Benz and BMW are among the automakers that are implementing more recycled plastic in response to the anticipated regulatory tightening in Europe. According to MarketsandMarkets, an India-based research company, the market for recycled materials for automobiles, including plastic, is expected to expand by approximately 60% from its current $2.2 billion in 2022 to $3.9 billion in 2027.

Greg Abel’s First Berkshire Hathaway Shareholder Letter Signals Continuity, Caution, and Capital Discipline

Greg Abel’s First Berkshire Hathaway Shareholder Letter Signals Continuity, Caution, and Capital Discipline  Can your cat recognise you by scent? New study shows it’s likely

Can your cat recognise you by scent? New study shows it’s likely  OpenAI Pentagon AI Contract Adds Safeguards Amid Anthropic Dispute

OpenAI Pentagon AI Contract Adds Safeguards Amid Anthropic Dispute  Pentagon Weighs Supply Chain Risk Designation for Anthropic Over Claude AI Use

Pentagon Weighs Supply Chain Risk Designation for Anthropic Over Claude AI Use  Stuck in a creativity slump at work? Here are some surprising ways to get your spark back

Stuck in a creativity slump at work? Here are some surprising ways to get your spark back  Parents abused by their children often suffer in silence – specialist therapy is helping them find a voice

Parents abused by their children often suffer in silence – specialist therapy is helping them find a voice  Trump Media Weighs Truth Social Spin-Off Amid $6B Fusion Energy Pivot

Trump Media Weighs Truth Social Spin-Off Amid $6B Fusion Energy Pivot  Britain has almost 1 million young people not in work or education – here’s what evidence shows can change that

Britain has almost 1 million young people not in work or education – here’s what evidence shows can change that  Hyundai Motor Group to Invest $6.26 Billion in AI Data Center, Robotics and Renewable Energy Projects in South Korea

Hyundai Motor Group to Invest $6.26 Billion in AI Data Center, Robotics and Renewable Energy Projects in South Korea  Debate over H-1B visas shines spotlight on US tech worker shortages

Debate over H-1B visas shines spotlight on US tech worker shortages  Snowflake Forecasts Strong Fiscal 2027 Revenue Growth as Enterprise AI Demand Surges

Snowflake Forecasts Strong Fiscal 2027 Revenue Growth as Enterprise AI Demand Surges  OpenAI Hires Former Meta and Apple AI Leader Ruomin Pang Amid Intensifying AI Talent War

OpenAI Hires Former Meta and Apple AI Leader Ruomin Pang Amid Intensifying AI Talent War  BlueScope Steel Shares Drop After Rejecting Revised A$15 Billion Takeover Bid

BlueScope Steel Shares Drop After Rejecting Revised A$15 Billion Takeover Bid  Yes, government influences wages – but not just in the way you might think

Yes, government influences wages – but not just in the way you might think  Glastonbury is as popular than ever, but complaints about the lineup reveal its generational challenge

Glastonbury is as popular than ever, but complaints about the lineup reveal its generational challenge