If you want to understand why some sandcastles are tall and have intricate structures while others are nearly shapeless lumps of sand, it helps to have a background in geotechnical engineering.

As a geotechnical engineering educator myself, I use sandcastles in the classroom to explain how interactions of soil, water and air make it possible to rebuild landscapes after mining metals critical to the energy transition.

Building a sandcastle comes down to the right mix of those three ingredients. Sand provides the structure, but it’s water between the sand grains that provides the force – in this case, suction – that holds the sand together. And without the right amount of air the water would just push the sand grains apart.

Not just any sand

Sand grains, according to the standards body ASTM International’s Unified Soil Classification System, are soil particles having a diameter of 0.003 inches (0.075 mm) to 0.187 inches (4.75 mm). Sands, by definition, have at least half their particles in that range. Silt or clay is soil with particles smaller than sand size. And soil with particles larger than sand size is gravel.

The size of particles, or grains, also determines the way sand looks and feels. The smallest sand grains have a texture almost like powdered sugar. The largest grains are more like the size of small dry lentils.

Most sand will work for building a sandcastle, but the best sand has two characteristics: grains of sand in several different sizes and grains with angular or rough edges. Variation in grain size allows smaller sand grains to fill the pockets, or pores, between the larger sand grains. The result is increased sand strength.

Sand grains that are more angular, with sharp corners on them, lock together better, making the sandcastle stronger. It’s the same reason a pile of angular wooden blocks will stay in a pile, but a pile of marbles will go everywhere.

This is also why, surprisingly, the best sand for sandcastles is not typically found on an island or a coastal beach. More angular grains of sand are usually found closer to mountains, their geologic source. These sand grains have not yet had their edges rounded off by wind and water. Professional sandcastle builders will go so far as to import river sand for their creations.

Finally, the closer together the sand grains are, the stronger the sand will be. Pressing wet sand together tightly, by compaction or tamping, squeezes sand grains together, decreasing the size of pores and increasing the effect water can have. Compaction also increases grain interlocking and, consequently, sand strength.

Water is key

Without water, sand just forms a pile. Too much water and sand flows like liquid. But between dry sand and saturated sand lies a wide range of moisture levels that enable sandcastle construction.

Water is cohesive, meaning that water likes to stick to water. But water also sticks to or climbs up certain surfaces. Look at a half-full glass of water and you will see the water going up the insides of the glass a little. Gravity still holds the water in the glass, but the water is trying to climb up and wet the surface. This tiny power struggle is what makes sandcastles possible.

Right where the air and water meet, there’s surface tension. The air-water interface pulls downward, trying to hold the water together against the competing forces of surface wetting, cohesion and gravity. Surface tension pulls the water together like the taut skin of a balloon. And surface tension also pulls sand grains together.

If the glass were much skinnier, like a straw, the water would rise higher and have more surface tension. The narrower the straw, the higher the water would rise. This phenomenon is called capillarity.

Water behaves the same way in wet sand. The pores, or spaces, between the sand grains are like a bunch of very tiny straws. Water forms tiny bridges between the grains. The water in these bridges is under tension, pulling the grains together by a force we geotechnical engineers call suction stress.

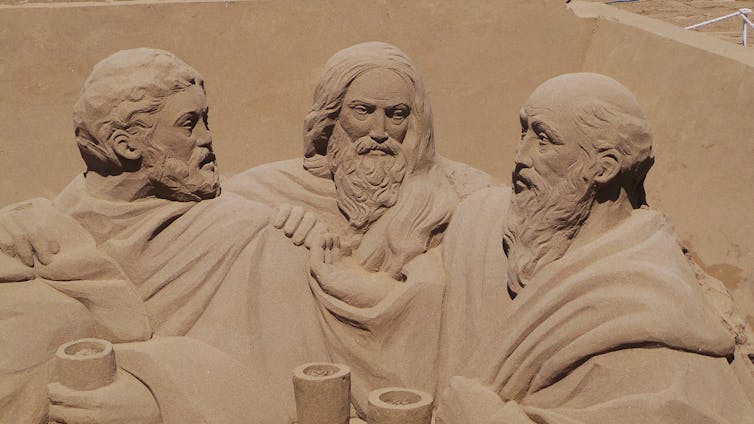

Did you know that suction is one of the forces holding this sand sculpture together? El Coleccionista de Instantes Fotografía & Video/Flickr, CC BY-SA

Just enough water

The quantity of water in the sand controls the size and strength of the water bridges. Too little water equals little bridges between the sand grains. More water, and the size and number of bridges grows, increasing the suction holding the sand grains together. The result is perfect sandcastle sand.

Too much water, though, and the suction is too weak to hold the sand together.

A general rule of thumb for building great sandcastles is one part water for every eight parts dry sand. Under ideal conditions in a laboratory, though, with dense sand and zero evaporation, one part water for every one hundred parts dry sand can produce wonders. At a beach, sand with the right moisture level is near the high tide line when the tide is low.

Incidentally, salt from seawater can also be a boon for sandcastle stability. Capillary forces hold sand grains together initially, but capillary water will eventually evaporate, particularly on a windy day. When sea water dries up, salt is left behind. Since the seawater was forming bridges between the grains, the salt crystallizes at these points of contact. In this way, salt can keep a sandcastle standing long after the sand has dried. But be careful not to disturb the salt-bonded sand; it’s brittle and collapsible.

To build a strong sandcastle, compact sand and a little water as tightly as you can. I prefer to create a dense mound and then scoop and carve away to reveal the art within. You can also compact the sand into buckets, cups or other molds, and build from the ground up. Just be sure to get the sand dense, and place the mold on a compacted foundation. Hands make for both a great compaction and carving tool, but a shovel or a seashell will allow for more precision. Have fun, and don’t be afraid to get sandy!

Joseph Scalia does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

Joseph Scalia, Associate Professor of Civil and Environmental Engineering, Colorado State University

Lost in space: MethaneSat failed just as NZ was to take over mission control – here’s what we need to know now

Lost in space: MethaneSat failed just as NZ was to take over mission control – here’s what we need to know now  CDC Vaccine Review Sparks Controversy Over Thimerosal Study Citation

CDC Vaccine Review Sparks Controversy Over Thimerosal Study Citation  SpaceX’s Starship Completes 11th Test Flight, Paving Way for Moon and Mars Missions

SpaceX’s Starship Completes 11th Test Flight, Paving Way for Moon and Mars Missions  NASA Partners with Katalyst to Save Swift Observatory with Innovative Docking Mission

NASA Partners with Katalyst to Save Swift Observatory with Innovative Docking Mission  FDA Pilot Program Eases Rules for Nicotine Pouch Makers

FDA Pilot Program Eases Rules for Nicotine Pouch Makers  Tabletop particle accelerator could transform medicine and materials science

Tabletop particle accelerator could transform medicine and materials science  Is space worth the cost? Accounting experts say its value can’t be found in spreadsheets

Is space worth the cost? Accounting experts say its value can’t be found in spreadsheets  Neuralink Plans High-Volume Brain Implant Production and Fully Automated Surgery by 2026

Neuralink Plans High-Volume Brain Implant Production and Fully Automated Surgery by 2026  Trump Administration to Launch Autism Initiatives Targeting Acetaminophen Use and New Treatment Options

Trump Administration to Launch Autism Initiatives Targeting Acetaminophen Use and New Treatment Options  Neuren Pharmaceuticals Surges on U.S. Patent Win for Rare Disorder Drug

Neuren Pharmaceuticals Surges on U.S. Patent Win for Rare Disorder Drug  Trump and Merck KGaA Partner to Slash IVF Drug Costs and Expand Fertility Coverage

Trump and Merck KGaA Partner to Slash IVF Drug Costs and Expand Fertility Coverage